-

Continue Reading

The Pivot Power House of Flexure Bearings

We are over stocked with our largest sized pivot bearing. That means it is the perfect time to request a sample of the C-Flex pivot bearing work horse, the JD-30 pivot. This 1” diameter double end pivot bearing won’t let you down. It has a torsional spring rate of 7.8023 lb-in/degree with load capacities up to 1800 lbs.

The radial stiffness of the JD-30 is 0.000005 inches of deflection per pound of load. Interested? Call for a FREE sample at 315-895-7454. EXPIRES ON 11/30/2016.

Download our free design guide and get more familiar with ways you can incorporate this quality component with infinite life into your application design.

Design Guide

This 1” diameter double end pivot bearing won’t let you down. It has a torsional spring rate of 7.8023 lb-in/degree with load capacities up to 1800 lbs.

The radial stiffness of the JD-30 is 0.000005 inches of deflection per pound of load. Interested? Call for a FREE sample at 315-895-7454. EXPIRES ON 11/30/2016.

Download our free design guide and get more familiar with ways you can incorporate this quality component with infinite life into your application design.

Design Guide

Learn more about C-Flex Bearing Co., Inc. and our expanding product line of pivot flexures and flexible couplings by downloading our brochure.

Company Brochure

Learn more about C-Flex Bearing Co., Inc. and our expanding product line of pivot flexures and flexible couplings by downloading our brochure.

Company Brochure

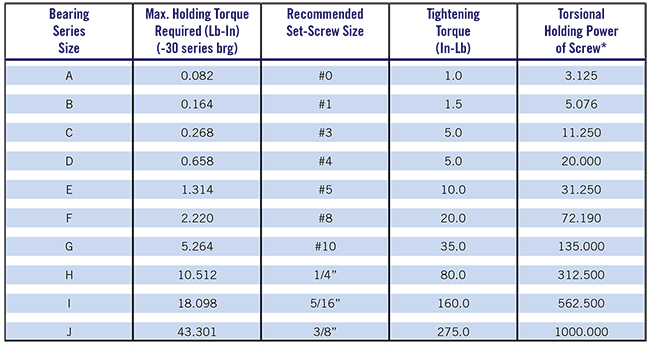

For information on set screw installation of the flex pivot, we offer a reference guide to help answer questions.

Set Screw and Tightening Torque Recommendations.

For information on set screw installation of the flex pivot, we offer a reference guide to help answer questions.

Set Screw and Tightening Torque Recommendations.

We have a sample waiting to ship to you today. Call us at 315-895-7454 or email at cflex@c-flex.com. Remember this offer EXPIRES ON 11/30/2016.

We have a sample waiting to ship to you today. Call us at 315-895-7454 or email at cflex@c-flex.com. Remember this offer EXPIRES ON 11/30/2016. -

Continue Reading

Staying Competitive in the Manufacturing Environment

As we have progressed through 2016 it has become evident that coordinating, planning, and implementing details in manufacturing has helped us stay competitive. We have purchased new machines which meant efficiently laying out shop floor space and employee time to continue offering the timely delivery of C-Flex product to our customers.

It is and always has been of utmost importance to C-Flex to pay attention to feedback and comments regarding our product and new development ideas so we may work on updates, customization, and logistical strategies. As a supplier to some of the worlds largest corporations, we are key to the success of their programs, products, and services. In order to meet industry demands, we prioritize quality and delivery. Quality means diverting discrepancies before they reach the customer’s door. Delivery means on time to purchase order contract. We continue to strive for 100% performance.

C-Flex Bearing Co., Inc. will continue working on new product developments for our coupling line. We will continue to work with customers on pivot bearing designs best suited for their needs. We will continue to motivate our employees to work for the success of not only C-Flex but for our loyal customer base. What can C-Flex do for you to help fuel your success? Call us at 315-895-7454 or email cflex@c-flex.com.

We want to hear from you soon!

What can C-Flex do for you to help fuel your success? Call us at 315-895-7454 or email cflex@c-flex.com.

We want to hear from you soon! -

Continue Reading

Standard Non-Catalog Pivot Designs

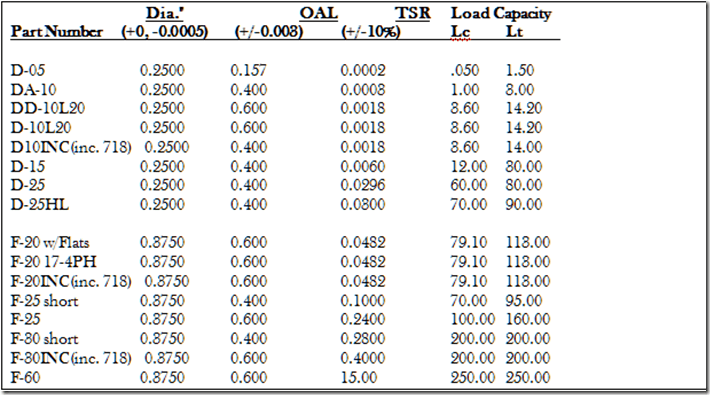

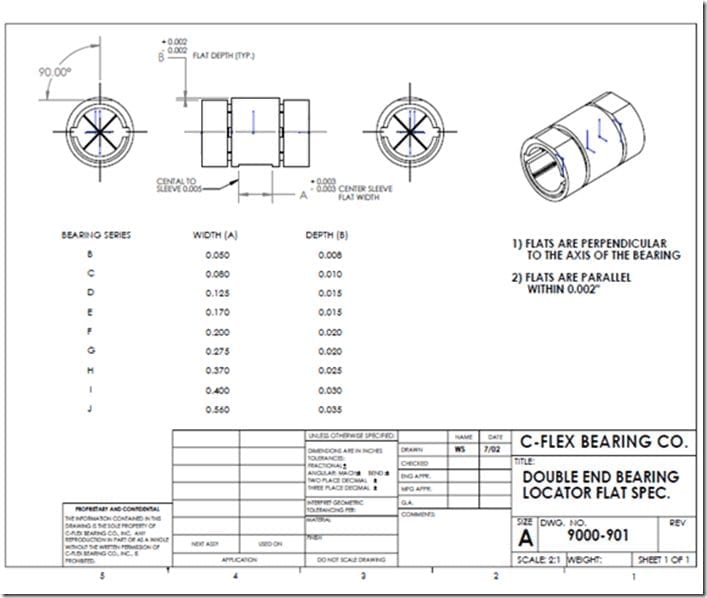

C-Flex is now in it's 23rd year of business and going strong. We are developing new products and customizing standard products for our customers. Among the many offerings are spring rates and diameters of extended length. These items, either cantilever or double end have an ?L? designation in their part number (e.g. D-20L10). ?L? indicated in increments of 0.010? how much longer (OAL) the pivot is than standard. To further explain, a D-20L10 would be 0.100? longer than the standard D-20 or 0.500? long, with the slot in the center as is normally provided. For double end versions, there is three, two digit suffixes which indicate: 1. the increase in overall length 2. the increase in length (if any) of the middle sleeve, and 3. the increase in length of the two outer sleeves. Here is another example: part number FD-10L20L10L05 indicates a FD-10 pivot bearing which includes an increase in overall length of 0.200? to a total OAL of 0.600?. The middle sleeve has been increased in length by 0.100? and each of the two outer sleeves have been increased by 0.050?. In the D size we offer the L version as a standard up to L40 (0.800? long) and the F Size OAL up to L60 (1.200? long). Additional sizes with varying torsional spring rates and load capacities may be available. C-Flex has manufactured many versions of our standard pivot bearing over the course of the companies 23 year history. Call us with your required torsional spring rate, load requirements, and any other specifications for your application. We might have a sample available for you to test. Listing of current designs available in 1/4? and 3/8?: In addition to the above, we currently manufacture two large, non-standard pivot bearings.

Part number J-40. Material is 400 series stainless steel. Diameter is 1?. Yield strength is 197 KSI. Ultimate tensile strength is 294 KSI. Fatigue strength is 75 KSI. Rated rotational angle is +/- 2.5 degrees for infinite life at zero load. Rated max. operating load is 2100 lbs. both radial and axial. Rated stiffness is 175,000 lbs./inch (radial and axial).

Part number K-30. Material is 400 series stainless steel. Dimensions are 1.25? dia. x 3.00? lg. Radial and Axial load capacity is 4500 lbs. Max. rotation for infinite life at zero load is +/- 2.6 degrees. Maximum rotation for infinite life with a 4500 lb. radial load is +/- 1.4 degrees. Torsional spring rate is 71.8 lb.-in/degree.

In addition to the above, we currently manufacture two large, non-standard pivot bearings.

Part number J-40. Material is 400 series stainless steel. Diameter is 1?. Yield strength is 197 KSI. Ultimate tensile strength is 294 KSI. Fatigue strength is 75 KSI. Rated rotational angle is +/- 2.5 degrees for infinite life at zero load. Rated max. operating load is 2100 lbs. both radial and axial. Rated stiffness is 175,000 lbs./inch (radial and axial).

Part number K-30. Material is 400 series stainless steel. Dimensions are 1.25? dia. x 3.00? lg. Radial and Axial load capacity is 4500 lbs. Max. rotation for infinite life at zero load is +/- 2.6 degrees. Maximum rotation for infinite life with a 4500 lb. radial load is +/- 1.4 degrees. Torsional spring rate is 71.8 lb.-in/degree. -

Continue Reading

Flexible Coupling Tips

Watch our NEW video! A short intro to our flexible coupling. http://www.couplingtips.com/flexible-couplings/video-two-types-flexible-couplings-c-flex/ https://www.youtube.com/watch?feature=player_detailpage&v=GIvqHV23dK4

Call for a sample! 315-895-7454

https://www.youtube.com/watch?feature=player_detailpage&v=GIvqHV23dK4

Call for a sample! 315-895-7454 -

Continue Reading

Get busy! It’s That Time of Year Again

It’s time to send SEASONS GREETINGS from C-Flex Bearing to you. Before the holidays consume your thoughts, think about getting everything done before

year end and deadlines creep up. Think about getting those flex pivots and flexible

couplings in house so there is one less order to place, one less deadline to worry about.

After your order is in our hands, we’ll get it processed and shipped to you right away.

Before the holidays consume your thoughts, think about getting everything done before

year end and deadlines creep up. Think about getting those flex pivots and flexible

couplings in house so there is one less order to place, one less deadline to worry about.

After your order is in our hands, we’ll get it processed and shipped to you right away.

Information on pivot sizes and performance properties can be found HERE:

https://c-flex.com/pivot-bearings/bearings-size-performance-properties/

Information on pivot sizes and performance properties can be found HERE:

https://c-flex.com/pivot-bearings/bearings-size-performance-properties/

Is it the coupling you want? Information and sizing can be found HERE:

For Lattice Style Couplings: https://c-flex.com/couplings-2/lattice-couplings/

For Super Plastic: https://c-flex.com/couplings-2/superplastic-couplings/

And if you REALLY want to surprise that design engineer in your facility, give him the

Gift of Ideas using the C-Flex Design Guide to make his hard work come true. Find it

HERE: https://c-flex.com/pivot-bearings/design-guide/

Is it the coupling you want? Information and sizing can be found HERE:

For Lattice Style Couplings: https://c-flex.com/couplings-2/lattice-couplings/

For Super Plastic: https://c-flex.com/couplings-2/superplastic-couplings/

And if you REALLY want to surprise that design engineer in your facility, give him the

Gift of Ideas using the C-Flex Design Guide to make his hard work come true. Find it

HERE: https://c-flex.com/pivot-bearings/design-guide/

We are here to help so don’t wait until the last minute when you should be enjoying the

holiday celebrations. Call us now at 315-895-7454 and we will wrap up your orders in plenty

of time so you can enjoy a very Happy Holiday!

We are here to help so don’t wait until the last minute when you should be enjoying the

holiday celebrations. Call us now at 315-895-7454 and we will wrap up your orders in plenty

of time so you can enjoy a very Happy Holiday! -

Continue Reading

Coupling News and CNC Milling

It has been busy times here at C-Flex these past two months. The popularity of the C-Flex Coupling has exploded! We even purchased a new HAAS MINI MILL to increase production. Since this new addition, we are in desperate need of an experienced CNC Machinist to program, set up and run these machines. This will be C-Flex’ 3rd mini mill actively running on our shop floor. EXCITING!

We even purchased a new HAAS MINI MILL to increase production. Since this new addition, we are in desperate need of an experienced CNC Machinist to program, set up and run these machines. This will be C-Flex’ 3rd mini mill actively running on our shop floor. EXCITING!

Questions Asked and Answered

While working with our customers, getting their orders ready, a few questions regarding the coupling have come up which might not be answered with clarity on our website. Let’s address these inquiries just in case anyone else has the same question/s.

Question: What is the temperature range of the C-Flex Lattice Coupling?

Answer: The couplings are the same material as our pivot bearings (400 series SS). Reference FAQ (remove the word “bearing”). The temperature range is –100 deg. F to 375 deg. F. The coupling can be held up to 450 degrees for no more than 8 hours otherwise damage may occur.

Question: On the data sheet for the English C-Flex Lattice Servo Coupling, 301500 couplings have an “H” dimension of 0.505 which is smaller than the smaller coupling. Is this correct?

Answer: There is an error in our catalog as well as the CAD model. All of the actual 1.25” diameter parts have an “H” dimension of 0.386 which is a logical value considering the size below and above it. The value was changed however the models and catalogs did not get updated.

Question: What is the Moment of Inertia for the smallest bore size of the Lattice Couplings?

Answer: For the 50XXXX Lattice Coupling

Coupling ID Bore (inches) MOI(lbs*In^2)

500750 0.125” 0.0042

501000 0.250” 0.0138

501250 0.375” 0.0350

501500 0.500” 0.1012

501750 0.625” 0.2020

502000 0.750” 0.3728

502500 0.875” 0.9636

For the 30XXXX Lattice SERVO Coupling

Coupling ID Bore (inches) MOI(lbs*In^2)

300750 0.0033” 0.125

301000 0.0145” 0.250

301250 0.0429” 0.375

301500 0.1091” 0.500

301750 0.2287” 0.625

302000 0.4444” 0.750

302500 1.3471” 0.875

Question: What IS the “H” Dimension?

The H dimension is the length of engagement of hub onto the shaft. The hub is internal to the flexures. A shaft can penetrate through the middle.

We continue to welcome more questions and comments so PLEASE give us a call. We’d love to talk to you about the C-Flex Flexible Coupling and the C-Flex Frictionless Bearing/Pivot. 315-895-7454 PHONE.

Questions Asked and Answered

While working with our customers, getting their orders ready, a few questions regarding the coupling have come up which might not be answered with clarity on our website. Let’s address these inquiries just in case anyone else has the same question/s.

Question: What is the temperature range of the C-Flex Lattice Coupling?

Answer: The couplings are the same material as our pivot bearings (400 series SS). Reference FAQ (remove the word “bearing”). The temperature range is –100 deg. F to 375 deg. F. The coupling can be held up to 450 degrees for no more than 8 hours otherwise damage may occur.

Question: On the data sheet for the English C-Flex Lattice Servo Coupling, 301500 couplings have an “H” dimension of 0.505 which is smaller than the smaller coupling. Is this correct?

Answer: There is an error in our catalog as well as the CAD model. All of the actual 1.25” diameter parts have an “H” dimension of 0.386 which is a logical value considering the size below and above it. The value was changed however the models and catalogs did not get updated.

Question: What is the Moment of Inertia for the smallest bore size of the Lattice Couplings?

Answer: For the 50XXXX Lattice Coupling

Coupling ID Bore (inches) MOI(lbs*In^2)

500750 0.125” 0.0042

501000 0.250” 0.0138

501250 0.375” 0.0350

501500 0.500” 0.1012

501750 0.625” 0.2020

502000 0.750” 0.3728

502500 0.875” 0.9636

For the 30XXXX Lattice SERVO Coupling

Coupling ID Bore (inches) MOI(lbs*In^2)

300750 0.0033” 0.125

301000 0.0145” 0.250

301250 0.0429” 0.375

301500 0.1091” 0.500

301750 0.2287” 0.625

302000 0.4444” 0.750

302500 1.3471” 0.875

Question: What IS the “H” Dimension?

The H dimension is the length of engagement of hub onto the shaft. The hub is internal to the flexures. A shaft can penetrate through the middle.

We continue to welcome more questions and comments so PLEASE give us a call. We’d love to talk to you about the C-Flex Flexible Coupling and the C-Flex Frictionless Bearing/Pivot. 315-895-7454 PHONE. -

Continue Reading

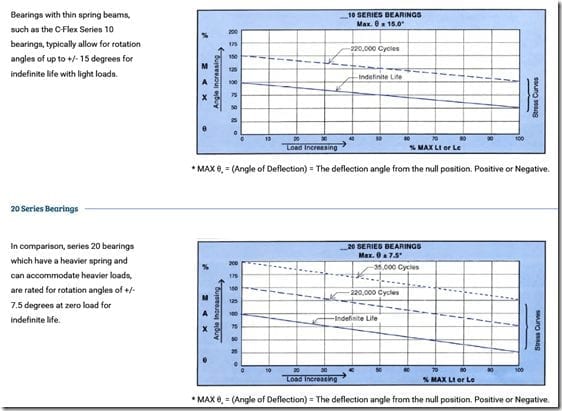

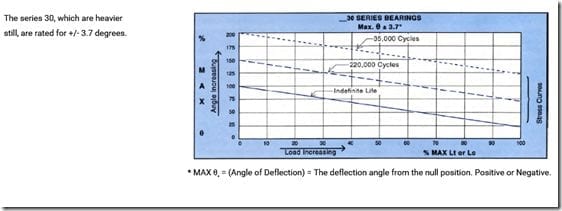

Maximum Rotation Angles of the C-Flex Pivot Bearing

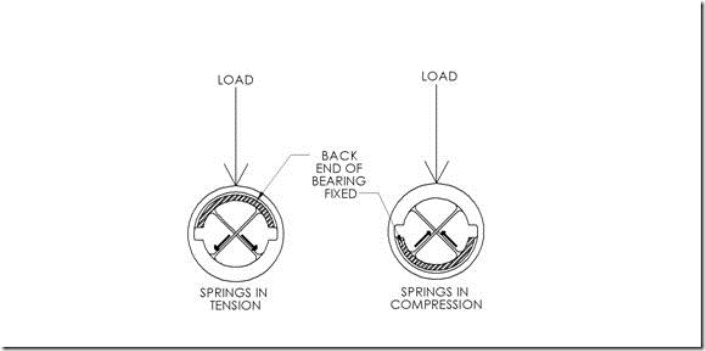

A question was asked by one of our customers concerning maximum rotation angles and hard stop limits.

The max rotation angles are limits set for recommended usage and not physical limits.

For example, in regards to the 10 series pivot bearings, C-Flex recommends maximum rotation

in one direction of 15 degrees for indefinite life and 30 degrees plus/minus rotation before damage occurs.

The C-Flex pivot bearing, in the 10 series will rotate a minimum of 30 degrees each way with the

actual hard stop occurring sometime after that, possibly at 35 degrees. This is similar to the 20 series which

will rotate at least 15 degrees each way and the 30 series which will rotate at least 7 degrees each way.

It is recommended that the user put stops in their application to prevent excessive rotation. If that is not possible,

we will customize the pivot bearing with limit stops so the springs will not be damaged if the stop are hit with

excessive force.

Reference the life cycle charts below: Also found on our site under LIFE PROJECTIONS

A question was asked by one of our customers concerning maximum rotation angles and hard stop limits.

The max rotation angles are limits set for recommended usage and not physical limits.

For example, in regards to the 10 series pivot bearings, C-Flex recommends maximum rotation

in one direction of 15 degrees for indefinite life and 30 degrees plus/minus rotation before damage occurs.

The C-Flex pivot bearing, in the 10 series will rotate a minimum of 30 degrees each way with the

actual hard stop occurring sometime after that, possibly at 35 degrees. This is similar to the 20 series which

will rotate at least 15 degrees each way and the 30 series which will rotate at least 7 degrees each way.

It is recommended that the user put stops in their application to prevent excessive rotation. If that is not possible,

we will customize the pivot bearing with limit stops so the springs will not be damaged if the stop are hit with

excessive force.

Reference the life cycle charts below: Also found on our site under LIFE PROJECTIONS

If using the solid models of the C-Flex pivot bearing, it will exceed recommended angles of rotation

or rather, will reflect rotation to the hard stops. Solid models can be found at our site under

?What We Do? => ?Pivot Bearings? => ?Downloadable Solid Models?.

Call us with any questions at 315-895-7454.

If using the solid models of the C-Flex pivot bearing, it will exceed recommended angles of rotation

or rather, will reflect rotation to the hard stops. Solid models can be found at our site under

?What We Do? => ?Pivot Bearings? => ?Downloadable Solid Models?.

Call us with any questions at 315-895-7454. -

Continue Reading

Life Cycle Testing of C-Flex Products

Life Cycle Testing of C-Flex Products You will consider many products and many scenarios before putting your design ideas into production. At C-Flex, we understand the importance of supplying products that won't repeatedly break down before their time. C-Flex Bearing life cycle testing services enable you to project the longevity of our product in your design before failure. Life expectancy of the C-Flex pivot is a result of fatigue on spring materials resulting from repeated applied loads and angles of rotation. If used within rated values, the user can expect indefinite life from the C-Flex pivot bearing. If however, the application requires exceeding any recommended limit, a finite and predictable life may be calculated. The charts provided in our catalogue reflect life lines for usage under a full range of motion about center. If the application requires rotation to only one side, C-Flex will help calculate the expected longevity of use within the application. *An example is provided on page 6, section III of the Design Guide . C-Flex has the facilities and expertise to conduct accelerated life cycle testing on our pivots and coupling products. This type of test is conducted using aggressive condition specifications based upon customer requests. Testing Services Breakdown: Life Cycle Test for 1 to 4 units. Standard lead time is 2 - 3 weeks depending on requirements of test. 10 million cycles at a +/- 2.5 degree offset is considered a standard customer defined test. Room temperature for all levels of testing with cycle speed of 1400/min. Number of cycles 10. The customer may define angle of rotation , number of units tested, and may request extended life testing e.g. 30 million cycles. [youtube http://www.youtube.com/watch?v=F_nPBNTKU4I?feature=player_embedded] https://www.youtube.com/watch?v=F_nPBNTKU4I or view the video here . Call us today at 315-895-7454 to talk to our engineers regarding your application and product testing requirements. We're here to help. -

Continue Reading

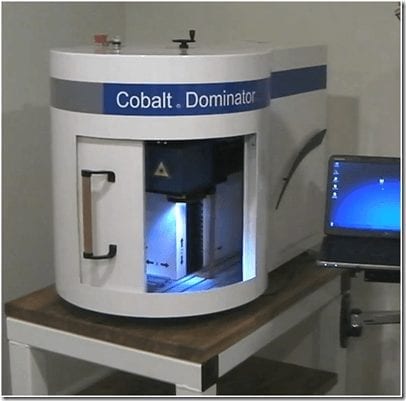

Efficiency Comes At Every Level – Laser Marking

C-Flex Bearing Co., Inc. considers itself a smart business and knows that tight cycle times with strong product quality keeps the customer satisfied. While the main focus is to reduce cost, it is never at the expense of quality at C-Flex Bearing. We rely on reductions in production variability in cycle times while enforcing error proofing at every level. This means best practices in the C-Flex production process. Breaking down efficiency even further to examination at a micro level, we look at the marking technology utilized at C-Flex and the benefits transferred to the customer. Laser Marking: A level in production which has saved final process time as well as increased customer satisfaction. It has been a few years since C-Flex Bearing Co., Inc. first introduced Laser Marking Technology via True Pulsed Fiber Laser into the final stage production process.

The old system of etching onto the metal part required we purchase bottles of chemicals for the marking process. The results were not crisp, clean, and were certainly not easily customized to customer part number identification.

It has been a few years since C-Flex Bearing Co., Inc. first introduced Laser Marking Technology via True Pulsed Fiber Laser into the final stage production process.

The old system of etching onto the metal part required we purchase bottles of chemicals for the marking process. The results were not crisp, clean, and were certainly not easily customized to customer part number identification.

The many benefits associated with laser marking, using a table top marking system, has increased efficiency and satisfaction for customers.

1. C-Flex can produce characters, logos, and bar codes with continuous lines to improve mark legibility.

2. A wide variety of text styles improve image and the customer sense of quality for the final product.

3. The laser mark is permanent on a variety of materials which prevents losing identifying information and is important to traceability.

4. The cost for custom marking to our customers is minimized.

5. The lack of chemicals and fluids creates a cleaner more sustainable environment.

6. Greater uptime because less maintenance, quick operator set up and utilization This is how it works:

The many benefits associated with laser marking, using a table top marking system, has increased efficiency and satisfaction for customers.

1. C-Flex can produce characters, logos, and bar codes with continuous lines to improve mark legibility.

2. A wide variety of text styles improve image and the customer sense of quality for the final product.

3. The laser mark is permanent on a variety of materials which prevents losing identifying information and is important to traceability.

4. The cost for custom marking to our customers is minimized.

5. The lack of chemicals and fluids creates a cleaner more sustainable environment.

6. Greater uptime because less maintenance, quick operator set up and utilization This is how it works:

A. Turn on the laptop . B. Set up mark on software. C. Place component into the machine. D. Adjust any settings/placement. E. Close the door and mark.

Not only is the resulting product marking for company identification, part number, and serial number traceability cleaner and cosmetically more pleasing to our customers, but it has reduced internal costs as well as increased production efficiency to the C-Flex manufacturing operations.

As we continue to support ongoing manufacturing transformations for not only production efficiency but a more proficient organization, the satisfaction from long time customers goes hand in hand. With efficiencies built into every process, C-Flex exists on a solid foundation yet remains flexible to capture new markets and drive customer loyalty.

but it has reduced internal costs as well as increased production efficiency to the C-Flex manufacturing operations.

As we continue to support ongoing manufacturing transformations for not only production efficiency but a more proficient organization, the satisfaction from long time customers goes hand in hand. With efficiencies built into every process, C-Flex exists on a solid foundation yet remains flexible to capture new markets and drive customer loyalty.

HomeCategory