-

Continue Reading

C-Flex Pivot Training Series

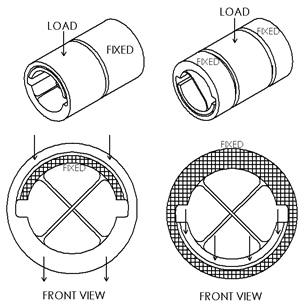

Sharpen your knowledge. Improve product designs. This C-Flex training page goes hand in hand with knowledgeable engineers to delve into areas where help is needed. Send us your current design challenges and leave with a plan for making a difference in your product. cflex@c-flex.com The following are four areas where you may be able to find a solution right on our website. How does the pivot work?

There is an outer sleeve and an inner core. The sleeves give the bearing a round exterior that can be mounted easily in a round hole. Since the sleeves do not affect the performance of

the internal springs, it's possible to have many different sleeve combinations of the same bearing such as cantilever or double ended. This allows for a wide range of mounting options that all have

the same performance characteristics. Conversely, It's possible to have the same sleeves with a wide variety of spring sizes inside to provide the desired performance characteristics.

The inner core. The core is the central element containing the springs which allow the bearing to rotate. Click here for more information….

How does the pivot work?

There is an outer sleeve and an inner core. The sleeves give the bearing a round exterior that can be mounted easily in a round hole. Since the sleeves do not affect the performance of

the internal springs, it's possible to have many different sleeve combinations of the same bearing such as cantilever or double ended. This allows for a wide range of mounting options that all have

the same performance characteristics. Conversely, It's possible to have the same sleeves with a wide variety of spring sizes inside to provide the desired performance characteristics.

The inner core. The core is the central element containing the springs which allow the bearing to rotate. Click here for more information….

What size should I select?

C-Flex Bearing Company offers two types of pivot bearings in 10 sizes with 3 spring series for each size resulting in 60 different standard parts in addition to a large number of custom pivot

bearings. Due to the fact that some of these bearings have overlapping properties it can be a confusing process to select the right pivot bearing. Click here for more information….

What size should I select?

C-Flex Bearing Company offers two types of pivot bearings in 10 sizes with 3 spring series for each size resulting in 60 different standard parts in addition to a large number of custom pivot

bearings. Due to the fact that some of these bearings have overlapping properties it can be a confusing process to select the right pivot bearing. Click here for more information….

How are they installed?

Clamp Screws: Take care to not over-tighten the clamp and crush the sleeve.

Epoxy: If possible, inject the epoxy around the outside of the bearing after it has been positioned in the mounting hole. Make sure that no epoxy gets into the core or between the core and the

sleeves of the bearing.

Shrink Fit: Cool the bearing to -100 °F using liquid nitrogen and heat the mounting hole. Quickly locate the bearing in mounting hole and hold in position until temperatures equalize and bearing is

secured. Shrink fit is typically permanent and cannot be undone without damaging bearing. Click here for more information….

How are they installed?

Clamp Screws: Take care to not over-tighten the clamp and crush the sleeve.

Epoxy: If possible, inject the epoxy around the outside of the bearing after it has been positioned in the mounting hole. Make sure that no epoxy gets into the core or between the core and the

sleeves of the bearing.

Shrink Fit: Cool the bearing to -100 °F using liquid nitrogen and heat the mounting hole. Quickly locate the bearing in mounting hole and hold in position until temperatures equalize and bearing is

secured. Shrink fit is typically permanent and cannot be undone without damaging bearing. Click here for more information….

I don’t see the required specifications for my application?

C-Flex Bearing Company can provide a vast array of custom alterations to the standard pivot bearings. If you have an application where a standard pivot bearing will not suffice then see if

one of the alterations we offer below will suit your needs. If you have a requirement that can't be met with the options listed here feel free to contact C-Flex and we can work with you to

create a custom product just for your application. Click here for more information….

Most questions can be answered by the information found on our website. However, if you don’t want to spend time looking, please call us at 315-895-7454 or email us at cflex@c-flex.com and we will be happy to work with you.

I don’t see the required specifications for my application?

C-Flex Bearing Company can provide a vast array of custom alterations to the standard pivot bearings. If you have an application where a standard pivot bearing will not suffice then see if

one of the alterations we offer below will suit your needs. If you have a requirement that can't be met with the options listed here feel free to contact C-Flex and we can work with you to

create a custom product just for your application. Click here for more information….

Most questions can be answered by the information found on our website. However, if you don’t want to spend time looking, please call us at 315-895-7454 or email us at cflex@c-flex.com and we will be happy to work with you.

-

Continue Reading

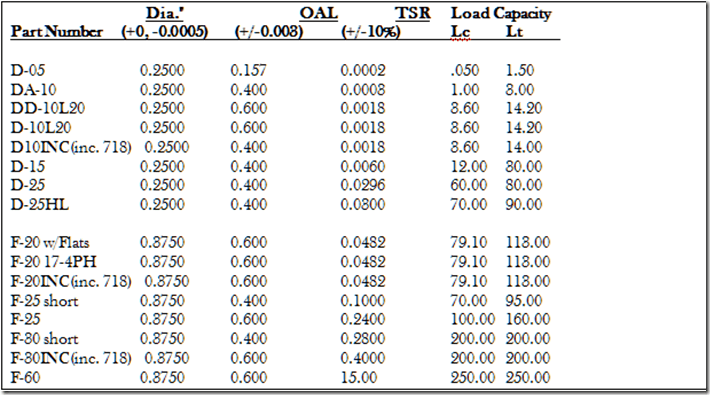

Standard Non-Catalog Pivot Designs

C-Flex is now in it's 23rd year of business and going strong. We are developing new products and customizing standard products for our customers. Among the many offerings are spring rates and diameters of extended length. These items, either cantilever or double end have an ?L? designation in their part number (e.g. D-20L10). ?L? indicated in increments of 0.010? how much longer (OAL) the pivot is than standard. To further explain, a D-20L10 would be 0.100? longer than the standard D-20 or 0.500? long, with the slot in the center as is normally provided. For double end versions, there is three, two digit suffixes which indicate: 1. the increase in overall length 2. the increase in length (if any) of the middle sleeve, and 3. the increase in length of the two outer sleeves. Here is another example: part number FD-10L20L10L05 indicates a FD-10 pivot bearing which includes an increase in overall length of 0.200? to a total OAL of 0.600?. The middle sleeve has been increased in length by 0.100? and each of the two outer sleeves have been increased by 0.050?. In the D size we offer the L version as a standard up to L40 (0.800? long) and the F Size OAL up to L60 (1.200? long). Additional sizes with varying torsional spring rates and load capacities may be available. C-Flex has manufactured many versions of our standard pivot bearing over the course of the companies 23 year history. Call us with your required torsional spring rate, load requirements, and any other specifications for your application. We might have a sample available for you to test. Listing of current designs available in 1/4? and 3/8?: In addition to the above, we currently manufacture two large, non-standard pivot bearings.

Part number J-40. Material is 400 series stainless steel. Diameter is 1?. Yield strength is 197 KSI. Ultimate tensile strength is 294 KSI. Fatigue strength is 75 KSI. Rated rotational angle is +/- 2.5 degrees for infinite life at zero load. Rated max. operating load is 2100 lbs. both radial and axial. Rated stiffness is 175,000 lbs./inch (radial and axial).

Part number K-30. Material is 400 series stainless steel. Dimensions are 1.25? dia. x 3.00? lg. Radial and Axial load capacity is 4500 lbs. Max. rotation for infinite life at zero load is +/- 2.6 degrees. Maximum rotation for infinite life with a 4500 lb. radial load is +/- 1.4 degrees. Torsional spring rate is 71.8 lb.-in/degree.

In addition to the above, we currently manufacture two large, non-standard pivot bearings.

Part number J-40. Material is 400 series stainless steel. Diameter is 1?. Yield strength is 197 KSI. Ultimate tensile strength is 294 KSI. Fatigue strength is 75 KSI. Rated rotational angle is +/- 2.5 degrees for infinite life at zero load. Rated max. operating load is 2100 lbs. both radial and axial. Rated stiffness is 175,000 lbs./inch (radial and axial).

Part number K-30. Material is 400 series stainless steel. Dimensions are 1.25? dia. x 3.00? lg. Radial and Axial load capacity is 4500 lbs. Max. rotation for infinite life at zero load is +/- 2.6 degrees. Maximum rotation for infinite life with a 4500 lb. radial load is +/- 1.4 degrees. Torsional spring rate is 71.8 lb.-in/degree.

HomeTag