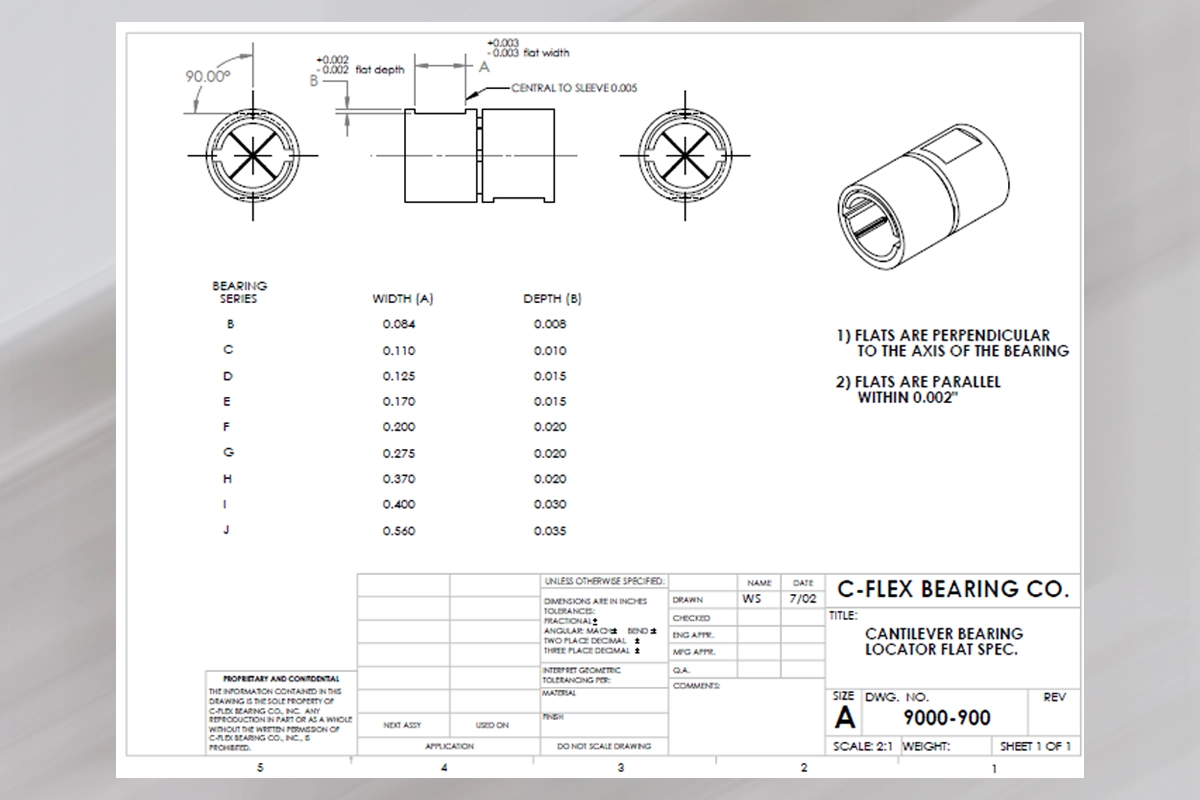

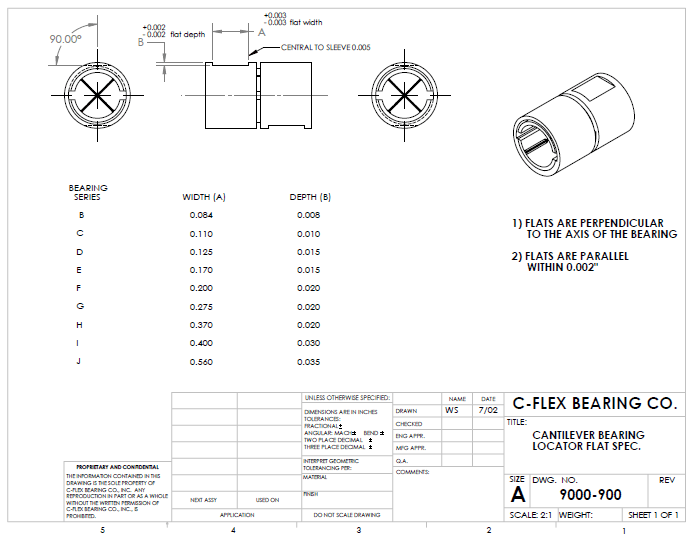

The locator flats are for use with a cup point or flat bottomed set screw so that when you tighten the set screw it will seat on the flat and align the bearing in the hole. Locator flats make installation a little easier and prevent the bearing from rotating in its mounting hole compared to using a set screw alone. They are especially useful for heavier pivots with high torsional spring rates.

Flat’s are generally used when bearing angle position is critical or high torques are being applied and there is a risk the bearing may slip in its mounting hole. There is not enough material on the thin side to cut flats, they can only be on the thick side.

Customer has the option of only one flat or two on a pivot.

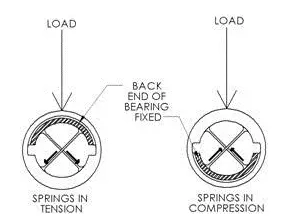

Types of Pivot Loading

Compression and tension loading refer to the forces on the springs in the center of the bearing. The springs are thin so if they are compressed they may buckle and fail at a lower load than if they were in tension. Basically you want to rotate the bearing in its mounting hole so that the force on the front end of the bearing is on the thin side. That being said the load capacity for an H-20 in compression is 221 pounds so if you are only applying 1 pound it won’t make a difference what position you use. In general, loading in tension is just a good habit to maintain.

Press fit mounting should be avoided since the force required to insert the bearing is usually higher than the load capacity of the bearing and can damage it. Using a set screw on the outside diameter or a clamp screw is sufficient for most applications, other methods are generally only used in high load applications.

Contact us with any questions at 315-895-7454. We are happy to help.