Unlock a world of possibilities in design and functionality with C-Flex bearings! Whether you’re developing intricate optical systems, sophisticated medical devices, or cutting-edge semiconductor machinery, our flex pivot bearings are your gateway to flawless operation and long-lasting performance.

News

Happy Holidays!

Unlock a world of possibilities in design and functionality with C-Flex bearings! Whether you’re developing intricate optical systems, sophisticated medical devices, or cutting-edge semiconductor machinery, our flex pivot bearings are your gateway to flawless operation and long-lasting performance.

Happy Halloween!

Unlock a world of possibilities in design and functionality with C-Flex bearings! Whether you’re developing intricate optical systems, sophisticated medical devices, or cutting-edge semiconductor machinery, our flex pivot bearings are your gateway to flawless operation and long-lasting performance.

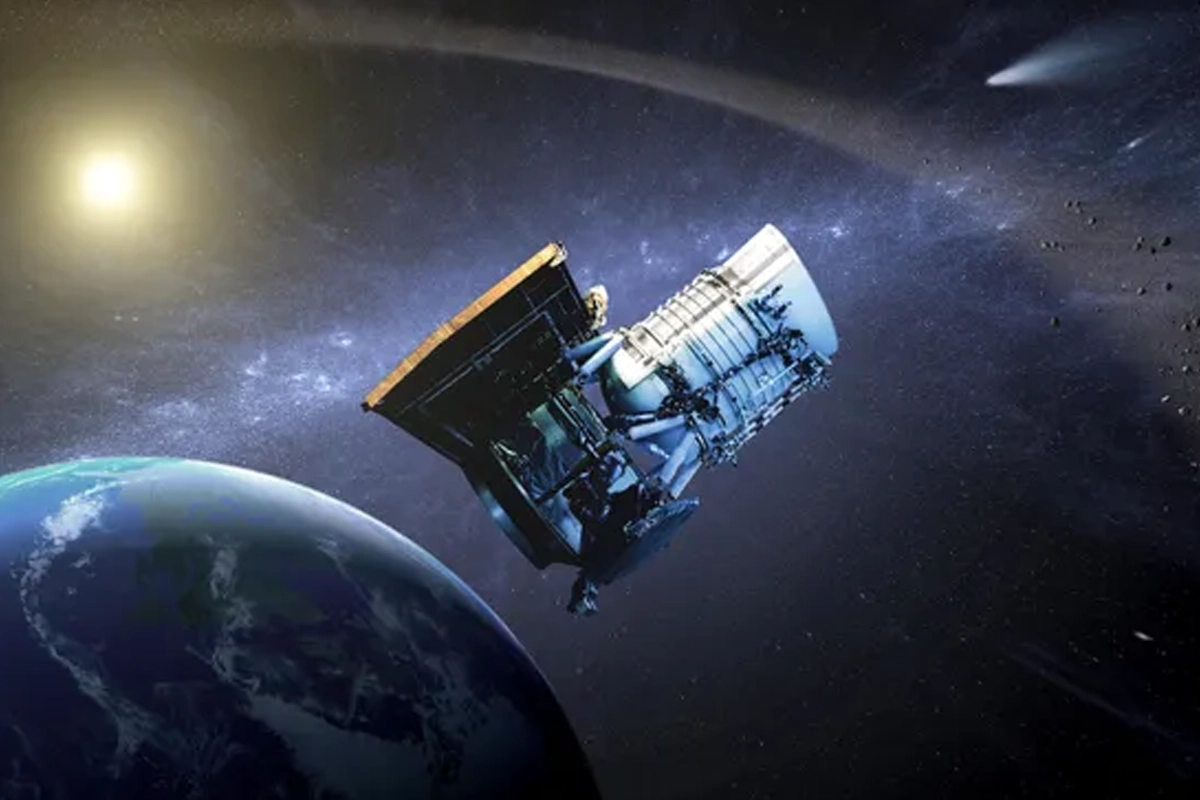

WISE Telescope, With C-Flex Bearings Inside, Re-Entering Atmosphere

Unlock a world of possibilities in design and functionality with C-Flex bearings! Whether you’re developing intricate optical systems, sophisticated medical devices, or cutting-edge semiconductor machinery, our flex pivot bearings are your gateway to flawless operation and long-lasting performance.

C-Flex Bearings Used In Vera C. Rubin Observatory

Unlock a world of possibilities in design and functionality with C-Flex bearings! Whether you’re developing intricate optical systems, sophisticated medical devices, or cutting-edge semiconductor machinery, our flex pivot bearings are your gateway to flawless operation and long-lasting performance.

Unlock a world of possibilities in design and functionality with C-Flex bearings! Whether you’re developing intricate optical systems, sophisticated medical devices, or cutting-edge semiconductor machinery, our flex pivot bearings are your gateway to flawless operation and long-lasting performance.

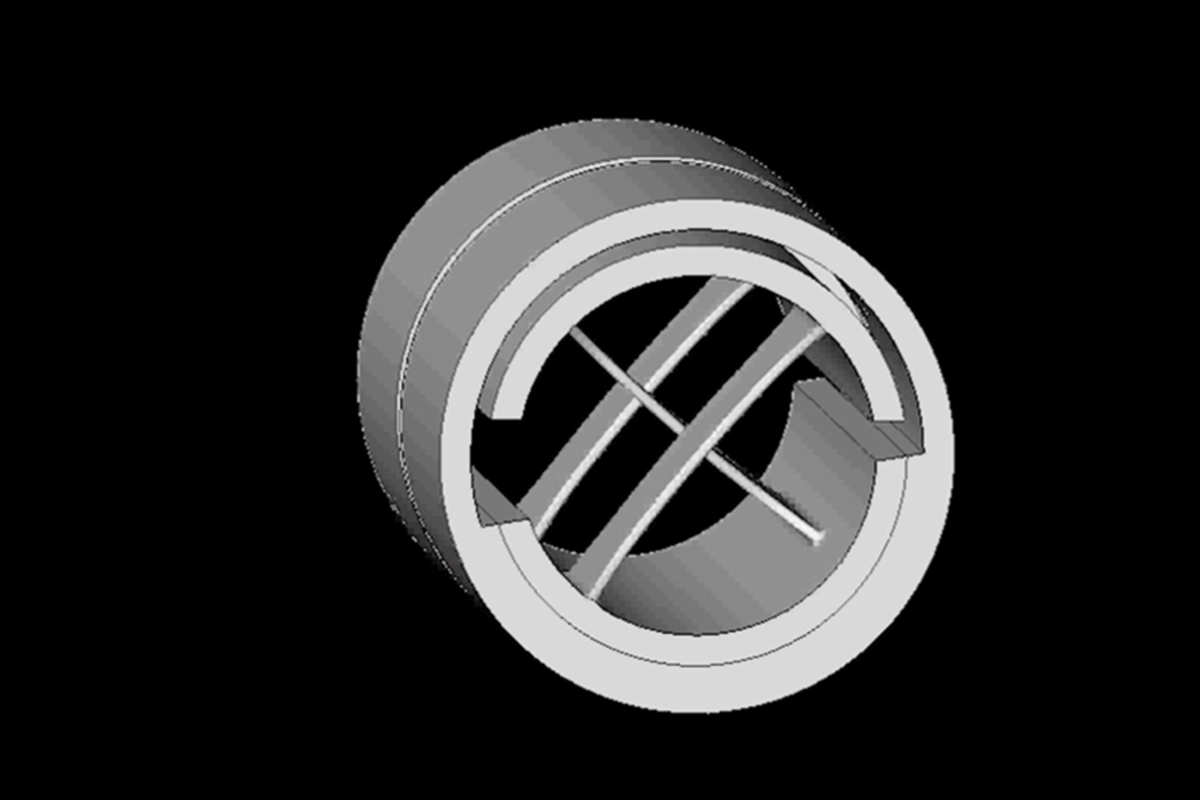

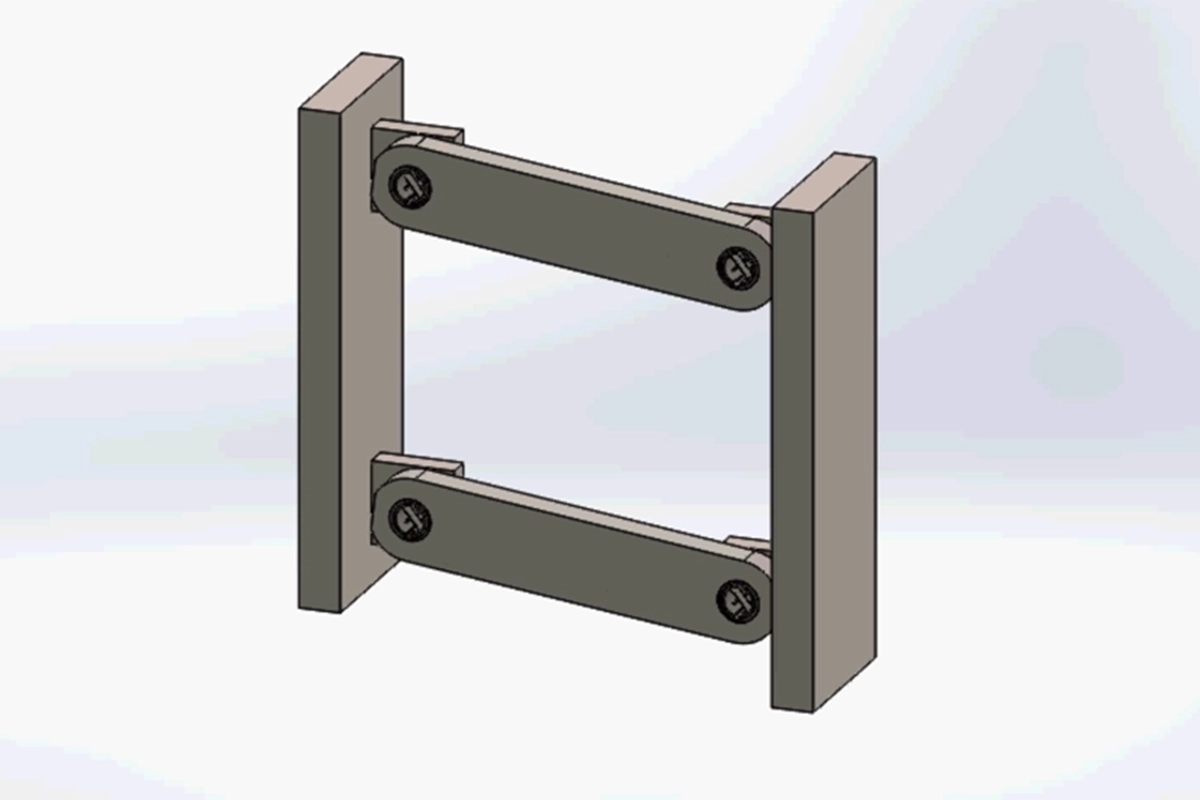

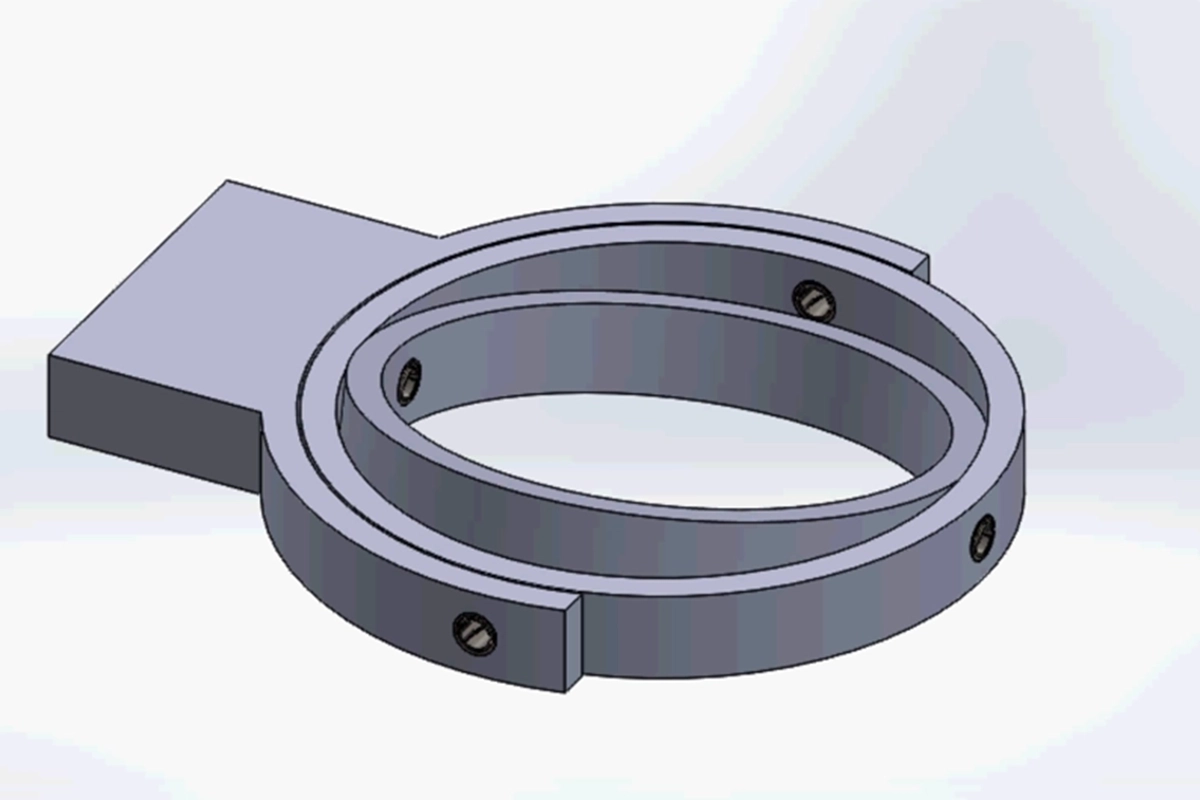

Unveiling Precision at Its Peak with C-Flex Pivot!

Step into the future of engineering with our cutting-edge C-Flex flex pivot! Imagine a bearing that provides not only flawless precision but also operates without friction, ensuring your machinery and devices perform at their best.

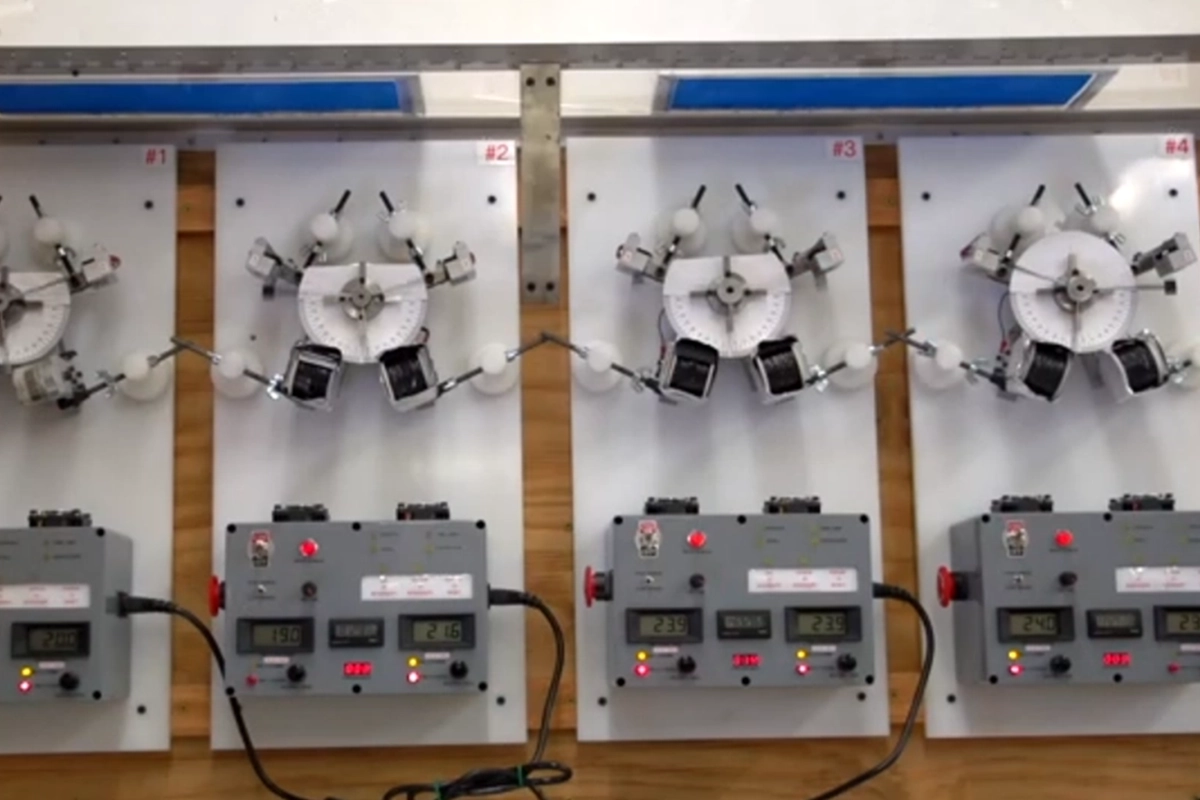

Elevate Your Innovations with C-Flex Bearings!

At C-Flex, we believe in empowering your creations with unparalleled accuracy and reliability. Our flex pivot bearings are designed to revolutionize how you approach motion in your projects, from robotics to optics.

Discover the Backbone of Advanced Technology

Dive into the core of advanced applications with C-Flex! Our bearings are more than just components; they’re the heart of high-precision and high-performance systems in gimbals, sensors, and beyond.

Going Green Technology Requirements:

Our pivots require no lubrication and contain no toxic materials resulting in zero environmental contamination.

C-Flex Bearing Company is a privately owned small business located in upstate New York, proudly serving the community since 1988.

We specialize in manufacturing frictionless bearings, pivots, and flexible couplings, customized to client specifications.

Company

Resources

Privacy Policy | Conflict Minerals Sourcing Policy

© C-Flex Bearing Company | All rights reserved. | Site Design by Pro Media.