SPECIAL REQUIREMENTS:

- Material: Inconel 718 with high phosphorus nickel braze

- TSR: High torsional spring rate

SPECIAL REQUIREMENTS:

Component material: Inconel 718

Braze Alloy: High Phosphorus Nickel Plate

I-40AMA5 Spring Material Properties:

Fatigue Strength: 77,000 psi

Yield Strength: 160,000 psi

Ultimate Tensile Strength: 196,000 psi

Modulus of Elasticity: 29,000,000 psi

Notes:

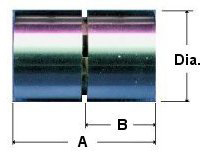

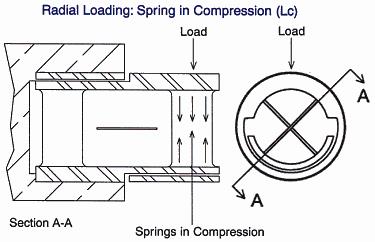

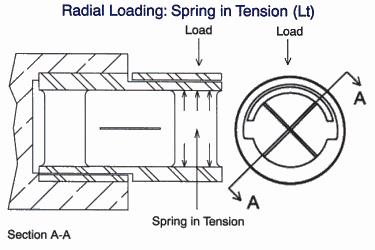

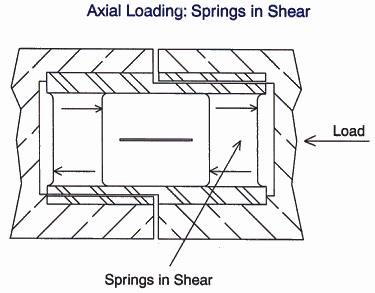

| Bearing Series | Diameter +.0000 -.0005 | A ±0.003 | B min | Load Capacity Lc | Load Capacity Lt | Load Capacity Axial | Radial Stiffness Lc | Radial Stiffness Lt | Axial Stiffness | Torsional Spring Rate |

|---|---|---|---|---|---|---|---|---|---|---|

| I-40AMA5 | 0.7500 | 1.200 | .564 | 900 | 900 | 900 | .000011 | .000011 | .000006 | 33.6 |

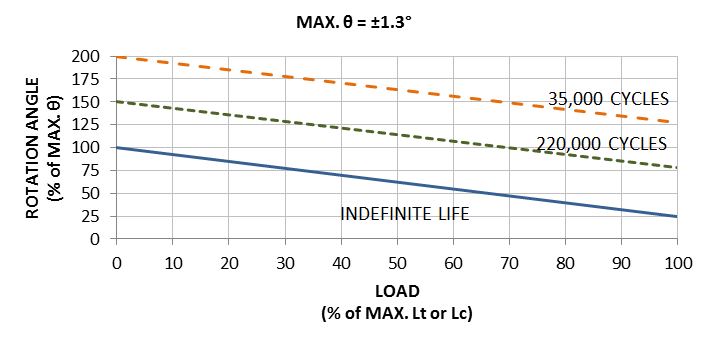

I-40AMA5 bearings have an indefinite life at ±1.3° of rotation and zero load. Life expectancy declines with increasing angles above ±1.3 ° and with increasing loads.

The C-Flex bearing or “pivot” is a cylindrical, limited rotational bearing, with a high relative radial and axial stiffness which is available in low, medium, or high torsional spring rates. It is typically available for maximum deflection angles of +/-30°, but various configurations are supplied upon request. It can be used simply as an oscillating unit or an extremely sensitive critical element. The bearing itself consists of two sleeves held in position by three leaf springs on two planes. There is no contact between the sleeves, eliminating friction. The springs provide the pivotal action which is inherently self centering, requires no lubrication or maintenance and has zero backlash. The bearing is also available with an additional sleeve allowing for central mounting providing two pivotal arms (the double end bearing, sizes AD to JD).