Resources

Helpful Resources

Download our comprehensive product catalog, bearing specification sheets, bearing design guide, and bearing simulation guide, providing essential information for selecting and implementing our products. Additionally, you can view set-screw size and tightening torques to ensure proper installation and performance. Click the links below to access these valuable resources and optimize your projects with C-Flex expertise.

Product Catalog

Explore the full range of products and technical specifications by downloading our comprehensive product catalog.

Specification Sheets

Explore detailed size and performance properties charts for our range of C-Flex bearings. These charts provide essential data to help you select the ideal bearing for your specific application, ensuring optimal performance and reliability. Discover how our precision-engineered bearings can meet your needs with their exceptional durability and efficiency.

Bearing Drawings

Our collection of technical drawings, are meticulously crafted to showcase the precision and innovation behind C-Flex Bearing Company’s high-performance components. Here, you’ll find detailed schematics and specifications that highlight our commitment to quality and engineering excellence.

Solid CAD Models

Unlock the precision and performance of C-Flex products by gaining instant access to our comprehensive library of Solid CAD Models.

Design Guide

This Pivot Bearing Design Guide is written with both the first time user and the experienced engineer in mind.

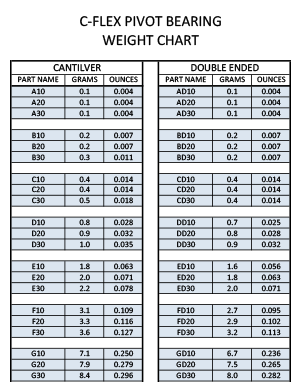

Weight Chart

The Pivot Bearing Weight Chart provides precise weight specifications for both our Cantilever and Double End Bearings.

Simulation Guide

The procedure outlined within this guide should be used to perform a finite element analysis of the pivot bearings.

Set-Screw Size and Tightening Torques

| Bearing Series Size | Max Holding Torque Required (Lb-In) (-30 series brg) | Recommended Set-Screw Size | Tightening Torque (In-Lb) | Torsional Holding Power of Screw* |

|---|---|---|---|---|

| A | 0.082 | #0 | 1.0 | 3.125 |

| B | 0.164 | #1 | 1.5 | 5.076 |

| C | 0.268 | #3 | 5.0 | 11.250 |

| D | 0.658 | #4 | 5.0 | 20.000 |

| E | 1.314 | #5 | 10.0 | 31.250 |

| F | 2.220 | #8 | 20.0 | 72.190 |

| G | 5.264 | #10 | 35.0 | 135.000 |

| H | 10.512 | 1/4" | 80.0 | 312.500 |

| I | 18.098 | 5/16" | 160.0 | 562.500 |

| J | 43.301 | 3/8" | 275.0 | 1000.000 |

Notes:

- * Using cup point set-screw.

- Set-screw must be positioned so as to apply pressure to the heavy (solid) section of the bearing sleeve. It is not recommended to position clamping screws over the under cut section of the sleeve, as buckling or collapse of the sleeve may occur.