Couplings

Flexible Shaft Couplings

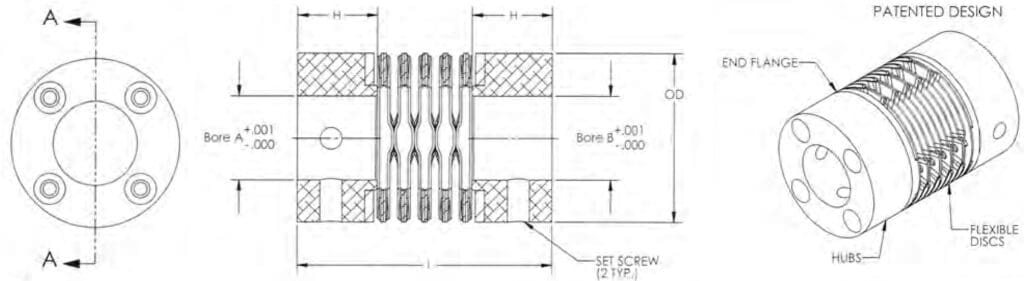

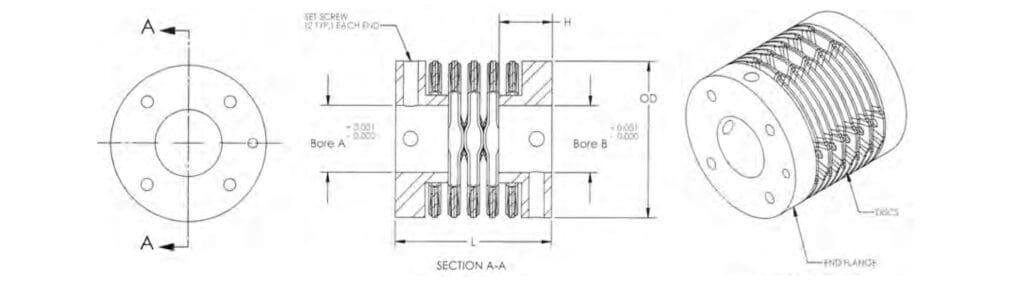

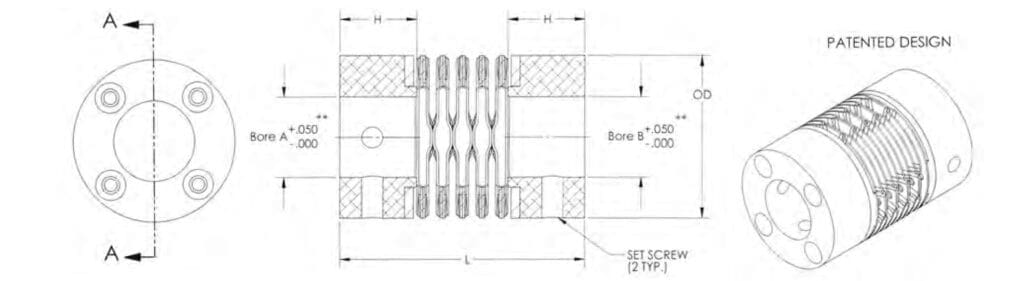

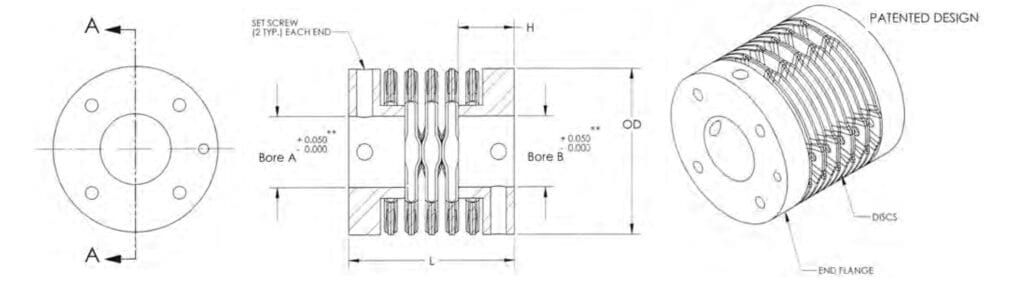

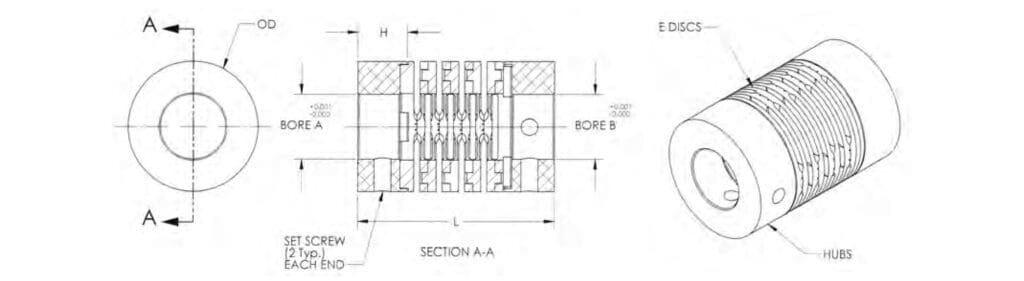

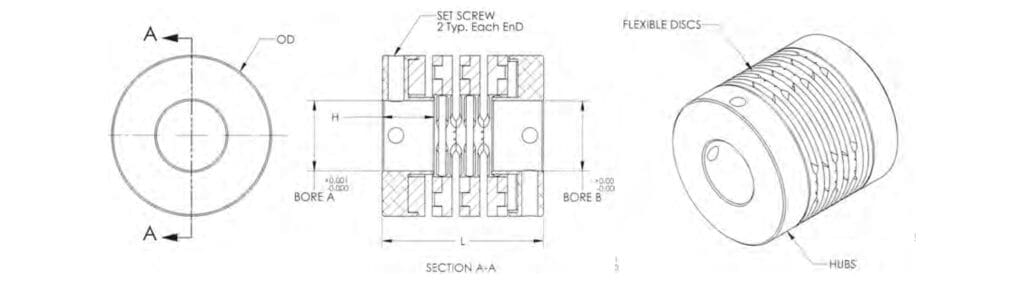

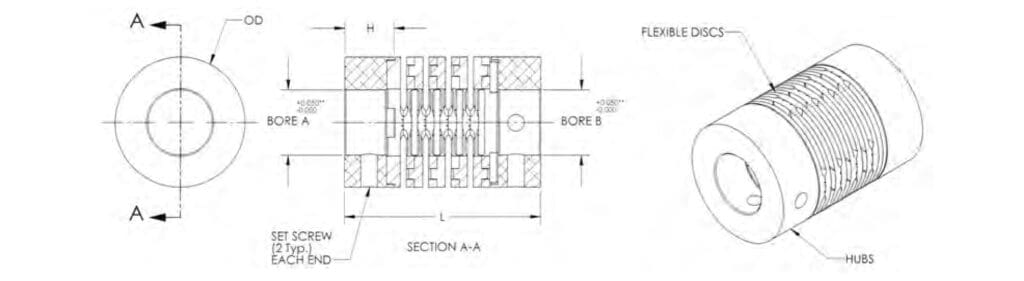

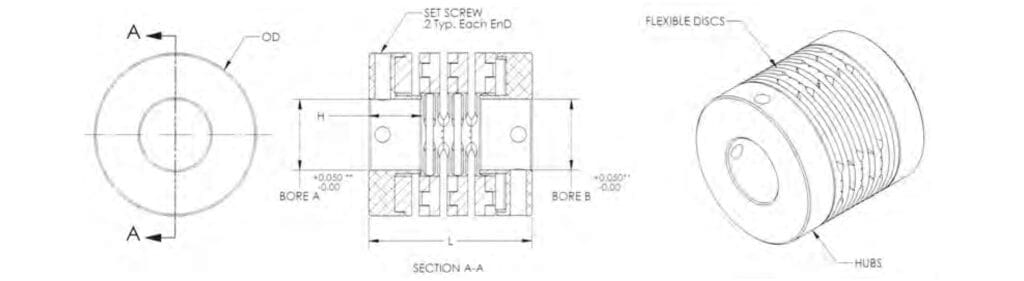

C-Flex couplings are designed to connect two rotating shafts, accommodating large misalignments while transmitting high torque loads with zero backlash. Their construction ensures a low moment of inertia and minimal impact on system dynamics. A large through hole allows for smaller couplings to fit larger shafts, and the ability to disassemble before installation makes them ideal for retrofit applications. These features make C-Flex couplings an efficient and versatile solution for various mechanical systems.

Features

- Misalignment Accommodation: Our couplings can handle angular, parallel, and axial misalignments, ensuring smooth and efficient operation.

- Vibration Reduction: Designed to minimize vibration, our couplings enhance the lifespan and performance of your machinery.

- High Torque Capacity: Capable of handling significant torque, our couplings are suitable for a wide range of industrial applications.

Uses

C-Flex couplings are used across various industries, including:

- Aerospace

- Automotive

- Industrial Machinery

- Medical Devices

- English Lattice Couplings

- English Lattice Servo Couplings

- Metric Lattice Couplings

- Metric Lattice Servo Couplings

English Lattice Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (Lb*In) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (oz.) | Static Torsional Stiffness (Lb*In/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 500750 | 0.75 | 1.375 | 0.125 | 0.375 | 0.475 | M4 X 0.7 | 12 | 10,000 | 7 | 0.01 | 0.02 | 0.74 | 11 |

| 50100 | 1 | 1.5 | 0.25 | 0.5 | 0.474 | M4 X 0.7 | 24 | 7,500 | 7 | 0.015 | 0.025 | 1.41 | 27 |

| 501250 | 1.25 | 1.65 | 0.375 | 0.625 | 0.46 | M5 X 0.8 | 48 | 7,500 | 7 | 0.015 | 0.03 | 2.16 | 51 |

| 501500 | 1.5 | 2.25 | 0.5 | 0.75 | 0.704 | M6 X 1.0 | 75 | 5,000 | 7 | 0.02 | 0.03 | 4.35 | 89 |

| 501750 | 1.75 | 2.6 | 0.625 | 0.875 | 0.755 | M6 X 1.0 | 135 | 5,000 | 7 | 0.02 | 0.04 | 6.69 | 135 |

| 502000 | 2 | 2.85 | 0.75 | 1 | 0.816 | M8 X 1.25 | 180 | 3,750 | 7 | 0.025 | 0.05 | 9.92 | 205 |

| 502500 | 2.5 | 3.1 | 0.875 | 1.25 | 0.793 | M8 X 1.25 | 300 | 3,750 | 7 | 0.025 | 0.05 | 16.45 | 395 |

English Lattice Servo Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (Lb*In) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (oz.) | Static Torsional Stiffness (Lb*In/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 300750 | 0.75 | 0.75 | 0.125 | 0.375 | 0.240 | M3 X 0.5 | 12 | 10,000 | 7 | 0.01 | 0.02 | 0.84 | 11 |

| 301000 | 1 | 1 | 0.25 | 0.5 | 0.345 | M3 X 0.5 | 24 | 7,500 | 7 | 0.015 | 0.025 | 1.6 | 27 |

| 301250 | 1.25 | 1.25 | 0.375 | 0.625 | 0.385 | M5 X 0.8 | 48 | 7,500 | 7 | 0.015 | 0.03 | 2.45 | 51 |

| 301500 | 1.5 | 1.5 | 0.5 | 0.75 | 0.505 | M5 X 0.8 | 75 | 5,000 | 7 | 0.05 | 0.03 | 4.94 | 89 |

| 301750 | 1.75 | 1.75 | 0.625 | 0.875 | 0.550 | M5 X 0.8 | 135 | 5,000 | 7 | 0.02 | 0.04 | 7.59 | 135 |

| 302000 | 2 | 2 | 0.75 | 1 | 0.555 | M5 X 0.8 | 180 | 3,750 | 7 | 0.025 | 0.05 | 11.26 | 205 |

| 302500 | 2.5 | 2.5 | 0.875 | 1.25 | 0.615 | M6 X 1.00 | 300 | 3,7510 | 7 | 0.025 | 0.05 | 18.67 | 395 |

Metric Lattice Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (N*m) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (g) | Static Torsional Stiffness (N*m/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 600750 | 19 | 35 | 4 | 10 | 12 | M4 X 0.7 | 1.4 | 10,000 | 7 | 0.25 | 0.51 | 21 | 1.2 |

| 60100 | 25.4 | 38 | 8 | 13 | 12 | M4 X 0.7 | 2.8 | 7,500 | 7 | 0.38 | 0.63 | 40 | 3.1 |

| 601250 | 31.7 | 42 | 14 | 16 | 12 | M5 X 0.8 | 5.6 | 7,500 | 7 | 0.38 | 0.76 | 61 | 5.8 |

| 601500 | 38.1 | 57 | 17 | 19 | 18 | M6 X 1.0 | 8.5 | 5,000 | 7 | 0.51 | 0.76 | 123 | 10 |

| 601750 | 44.5 | 66 | 20 | 23 | 19 | M6 X 1.0 | 15.3 | 5,000 | 7 | 0.51 | 1 | 190 | 15 |

| 60200 | 50.8 | 72 | 24 | 26 | 21 | M8 X 1.25 | 20.5 | 3,750 | 7 | 0.63 | 1.25 | 281 | 23 |

| 600750 | 63.5 | 79 | 27 | 32 | 20 | M8 X 1.25 | 34 | 3,750 | 7 | 0.63 | 1.25 | 466 | 45 |

Metric Lattice Servo Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (N*m) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (g) | Static Torsional Stiffness (N*m/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 400750 | 19 | 19 | 4 | 10 | 6 | M3 X 0.5 | 1.4 | 10,000 | 7 | 0.25 | 0.51 | 23.8 | 1.2 |

| 40100 | 25.4 | 25.4 | 8 | 13 | 8.7 | M3 X 0.5 | 2.8 | 7,500 | 7 | 0.38 | 0.63 | 45.4 | 3.1 |

| 401250 | 31.7 | 31.7 | 14 | 16 | 9.8 | M5 X 0.8 | 5.6 | 7,500 | 7 | 0.38 | 0.76 | 69.2 | 5.8 |

| 401500 | 38.1 | 38.1 | 17 | 19 | 12.8 | M5 X 0.8 | 8.5 | 5,000 | 7 | 0.51 | 0.76 | 139.6 | 10 |

| 401750 | 44.5 | 44.5 | 20 | 23 | 14 | M5 X 0.8 | 15.3 | 5,000 | 7 | 0.51 | 1 | 215.6 | 15 |

| 40200 | 50.8 | 50.8 | 24 | 26 | 14 | M5 X 0.8 | 20.5 | 3,750 | 7 | 0.63 | 1.25 | 319 | 23 |

| 400750 | 63.5 | 63.5 | 27 | 32 | 15.6 | M6 X 1.00 | 34 | 3,750 | 7 | 0.63 | 1.25 | 529 | 45 |

- English SuperPlastic Coupling

- English SuperPlastic Servo Coupling

- Metric SuperPlastic Coupling

- Metric SuperPlastic Servo Coupling

English SuperPlastic Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (Lb*In) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (oz.) | Static Torsional Stiffness (Lb*In/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 540500 | 0.5 | 0.85 | 0.125 | 0.25 | 0.234 | M3 X 0.5 | 5 | 10,000 | 7 | 0.005 | 0.008 | 0.55 | 1.0 |

| 541000 | 1 | 1.5 | 0.25 | 0.5 | 0.381 | M4 X 0.7 | 20 | 7,500 | 7 | 0.008 | 0.012 | 0.93 | 8.3 |

| 541500 | 1.5 | 2.2 | 0.375 | 0.75 | 0.548 | M5 X 0.8 | 50 | 5,000 | 7 | 0.01 | 0.018 | 3.1 | 28 |

| 542000 | 2 | 2.75 | 0.5 | 1 | 0.639 | M6 X 1.0 | 120 | 3,750 | 7 | 0.01 | 0.02 | 6.98 | 67 |

| 542500 | 2.5 | 3.25 | 0.625 | 1.25 | 0.711 | M8 X 1.25 | 200 | 3,750 | 7 | 0.01 | 0.02 | 11.63 | 129 |

English SuperPlastic Servo Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (Lb*In) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (oz.) | Static Torsional Stiffness (Lb*In/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 340500 | 0.5 | 0.625 | 0.125 | 0.187 | 0.272 | M3 X 0.5 | 5 | 10,000 | 5 | 0.003 | 0.006 | 0.3 | 1.5 |

| 341000 | 1 | 1 | 0.25 | 0.437 | 0.325 | M4 X 0.7 | 20 | 7,500 | 5 | 0.005 | 0.008 | 0.5 | 12 |

| 341500 | 1.5 | 1.5 | 0.375 | 0.625 | 0.525 | M5 X 0.8 | 50 | 5,000 | 5 | 0.007 | 0.013 | 1.67 | 40 |

| 342000 | 2 | 2 | 0.5 | 0.75 | 0.625 | M6 X 1.0 | 120 | 3,750 | 5 | 0.007 | 0.014 | 3.75 | 90 |

| 342500 | 2.5 | 2.5 | 0.625 | 1 | 0.75 | M8 X 1.25 | 200 | 3,750 | 5 | 0.007 | 0.014 | 6.25 | 175 |

Metric SuperPlastic Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (N*m) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (g) | Static Torsional Stiffness (N*m/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 640500 | 12.7 | 21.6 | 4 | 6 | 5.9 | M3 X 0.5 | 0.6 | 10,000 | 7 | 0.13 | 0.2 | 15.6 | 0.11 |

| 641000 | 25.4 | 38.1 | 6 | 12 | 9.7 | M4 X 0.7 | 2.3 | 7,500 | 7 | 0.2 | 0.3 | 26.3 | 2.0 |

| 641500 | 38.1 | 55.9 | 10 | 19 | 14 | M5 X 0.8 | 5.7 | 5,000 | 7 | 0.25 | 0.46 | 87.9 | 3.2 |

| 642000 | 50.8 | 69.8 | 13 | 25 | 16.2 | M6 X 1.0 | 13.6 | 3,750 | 7 | 0.25 | 0.51 | 198 | 7.6 |

| 642500 | 63.5 | 82.6 | 16 | 32 | 18 | M8 X 1.25 | 22.6 | 3,750 | 7 | 0.25 | 0.51 | 330 | 14.6 |

Metric SuperPlastic Servo Coupling

| P/N | OD | L | Min Bore A/B | Max Bore A/B | H | Set Screw Size | Max Torque (N*m) | Max RPM | Max Angular Offset (Deg.) | Max Parallel Offset | Max Axial Offset | Weight (g) | Static Torsional Stiffness (N*m/Deg) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 440500 | 12.7 | 15.9 | 4 | 5 | 7 | M3 X 0.5 | 0.6 | 10,000 | 5 | 0.08 | 0.15 | 8.5 | 0.17 |

| 441000 | 25.4 | 25.4 | 6 | 11 | 8.3 | M4 X 0.7 | 2.3 | 7,500 | 5 | 0.13 | 0.2 | 14.2 | 1.4 |

| 441500 | 38.1 | 38.1 | 10 | 16 | 13.3 | M5 X 0.8 | 5.7 | 5,000 | 5 | 0.18 | 0.33 | 47.3 | 4.5 |

| 442000 | 50.8 | 50.8 | 13 | 19 | 15.9 | M6 X 1.0 | 13.6 | 3,750 | 5 | 0.18 | 0.36 | 106 | 10.2 |

| 442500 | 63.5 | 63.5 | 16 | 25 | 19 | M8 X 1.25 | 22.6 | 3,750 | 5 | 0.18 | 0.36 | 177 | 20.0 |

Durable and Reliable Construction

C-Flex couplings are constructed using high-strength hardened stainless steel or glass-impregnated polyamide flexures, ensuring no maintenance is required for years of trouble-free operation, even in contaminated environments. These couplings are directionally independent, providing the same torsional rigidity and offset capability regardless of rotation direction.

Durable and Reliable Construction

C-Flex couplings are constructed using high-strength hardened stainless steel or glass-impregnated polyamide flexures, ensuring no maintenance is required for years of trouble-free operation, even in contaminated environments. These couplings are directionally independent, providing the same torsional rigidity and offset capability regardless of rotation direction.

Custom Solutions

Custom Couplings For Specific Requirements

We offer custom coupling solutions tailored to your specific requirements. Whether you need unique dimensions, materials, or performance characteristics, our engineering team can design and produce couplings that meet your exact needs.

Efficient System Performance

Using C-Flex couplings in mechanical systems to connect rotating shafts reduces energy usage and bearing failure by minimizing stress on bearings. Misalignment forces generate heat, which is wasted energy, but C-Flex couplings significantly reduce these forces, resulting in a more energy-efficient system.

Efficient System Performance

Using C-Flex couplings in mechanical systems to connect rotating shafts reduces energy usage and bearing failure by minimizing stress on bearings. Misalignment forces generate heat, which is wasted energy, but C-Flex couplings significantly reduce these forces, resulting in a more energy-efficient system.

Superior Technology at Low Cost

C-Flex couplings offer advanced technology at an affordable price. Choosing the correct coupling for your application ensures exceptional longevity, even in the harshest environments. These couplings provide reliable performance, reducing energy usage and bearing failure, ultimately leading to a more efficient system.

Secure Clamping Options

C-Flex couplings typically come with two set screws positioned at 90 degrees for shaft clamping. Alternatively, they can be equipped with C-Flex’s patent-pending progressive clamp bushings for secure, mark-free clamping. Additionally, a collet-style shaft locking design for the lattice servo coupling is under development and will be available soon.

Technical Data

For detailed technical information on pivot bearings, including loading diagrams, life projections, bearing centershift, stiffness properties, and hysteresis, please download our product catalog.

Get Started!

Ready to learn more about our products or place an order? Fill out the form below to inquire about obtaining C-Flex flexible couplings, or custom solutions. Our team will promptly respond with the information and assistance you need to get started. We look forward to helping you find the perfect solutions for your applications.

"*" indicates required fields